Production

Would you like to know more about our print work processes?

Stock in our warehouse:

- Grey cardboard in various weights and dimensions

- Duplex cardboard

- Corrugated cardboard in various qualities (E-, EE-, B-, EB-, etc.)

- Open corrugated cardboard (glued on one side)

Cutting:

With our ‘POLAR 155’ cutter, we can cut your materials to the format you need.

Other processes, such as cropping, bending, and zipping, are also possible.

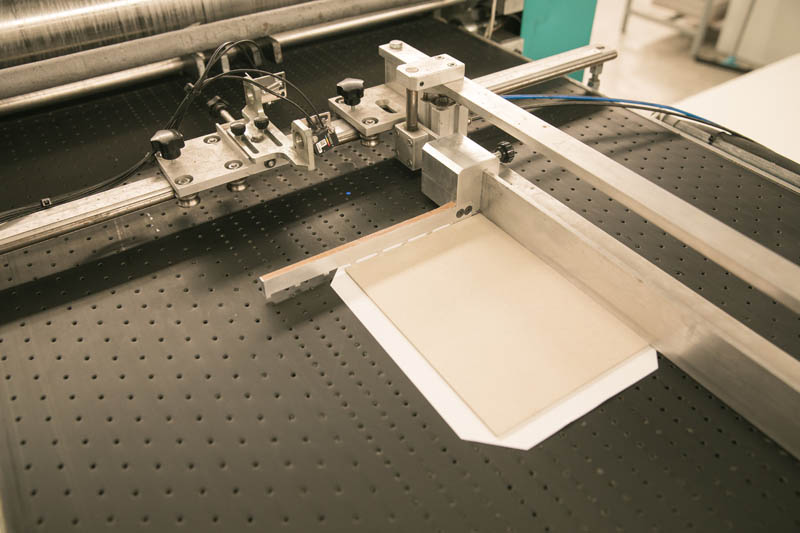

Laminating :

- Fully automatic laminating of paper up to 1200 x 1600 mm format on various carriers. This involves glueing a printing sheet (both recto and recto/verso), usually maco 150 g, on a selected cardboard quality such as grey or corrugated cardboard.

- If you choose open corrugated cardboard, we will supply a printing sheet in GC or GD duplex cardboard. This results in sturdy packaging.

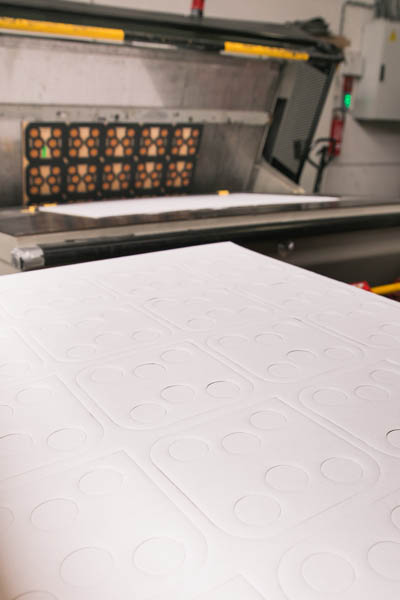

Hole-punching:

We punch up to 1200 x 1600 mm format. And from paper to cardboard, between 3 and 4 mm thickness. Our machines can easily handle various qualities of corrugated cardboard.

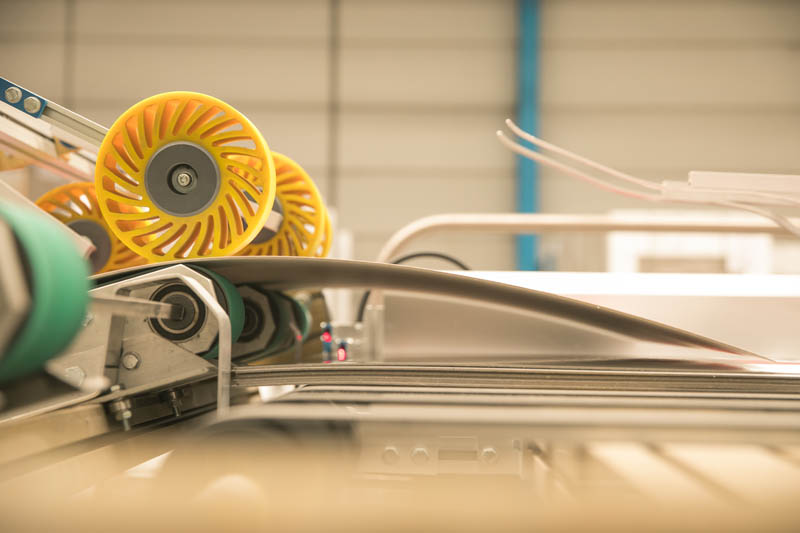

Box glueing machines:

Our box glueing machines (both automatic and semi-automatic) produce base and lid boxes.

Hole-punching:

We punch up to 1200 x 1600 mm format. And from paper to cardboard, between 3 and 4 mm thickness. Our machines can easily handle various qualities of corrugated cardboard.

Box glueing machines:

Our box glueing machines (both automatic and semi-automatic) produce base and lid boxes.

Glueing machines and flat glueing machines:

- Paper borders around cardboard for items such as calendars, placards, ring-binders,

- Glueing paper to grey cardboard

- Duplexing and triplexing: glueing various layers together.

Additional finishes:

- Stapling / stitching boxes

- Pleated folds, glueing along the seam

- Semi-automatic glueing along the seam

- Semi-automated spot glueing

- Applying tape packaging / placards

- Assembling displays

- Filling and individual packaging

- Logistics and transport